Tại sao lại có ống vây?

Compared with bare tube, fin tube has more advantages.

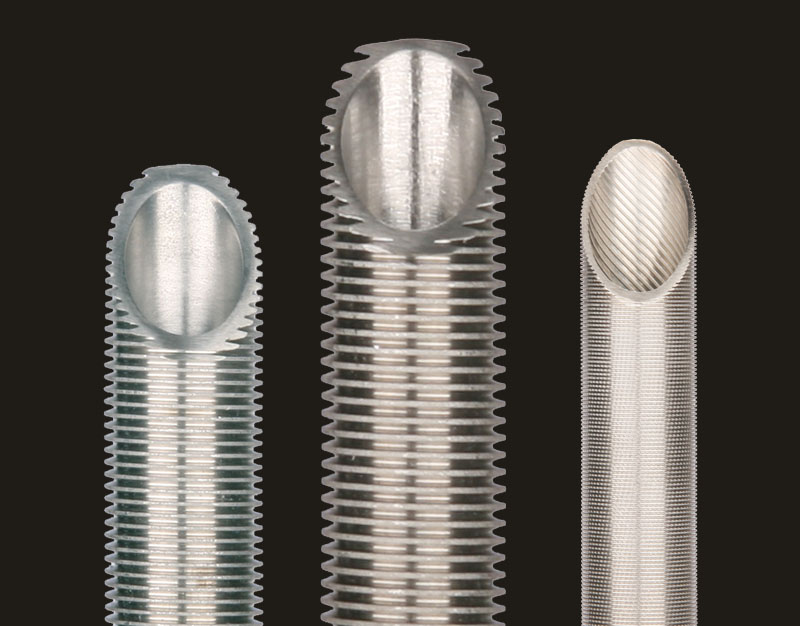

Let's take titanium integral low fin tube as an example.

Basically it would create 3 times heat transfer efficiency using titanium low fin tube, therefore less and shorter tubes would be needed for same heat transfer. The event of using less and shorter tubes means that the weight and volume of heat exchanger would be reduced. It would lead to saving on other materials used in heat exchanger such as titanium shell, titanium tubesheet, shaft, baffle plate, etc.

From cost wise, even though the unit price for fin tube is higher than that of bare tube, it would still be cost saving solution eventually after comprehensively calculation from all aspects.

What about the fouling? It's also advantage of fin tube, thanks to the structure of fin tube, it enhances the scale cleaning ability and there was experiment done showing that low fin tube accumulates far less scale than a bare tube operating within a same heat exchanger.

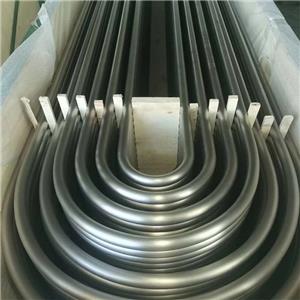

What is the application of fin tube nowadays? Normally power plants, Chemical industry, Heat recovery plant and Heating industry are the applications for fin tube.

Jiangsu Votti(Xuyi Titan) has exported all kinds of fin tubes every year including titanium fin tube, bimetallic fin tube, stainless steel fin tube etc. And clients were all satisfied , happy and benefit from the fin tubes.